New Type PU Sandwich Panel Production Line

With Automatically Cutting System

Brief introduction of production line

This PU Sandwich panel production line is an automatic production

line. In the PU sandwich panel producing procedure, the product

line can continuously produce sandwich panel with PU as its core

material. The liquid state raw materials were continuously injected

into the middle of three formed panels and

reacting,foaming,solidifying in the double-rubber ,the PU sandwich

panel could be cut out automatically according to the required

length for users.

This PU panel line consists of 10 tons automatic de-coiler with

loading car, chain driven transmission, roll former, PU forming

machine, PU panel conveyor, non-stop cutting device, electric

controlling system.

Main technology parameters of production

- Production Material(mm):(0.25-1.0)×L, yield strength≤G300 Colored

steel

- Production speed:4-8 M/min

- Production type: totally continuous production with PLC controlling

- PU foam thickness: 25-100mm

- Composite structure:position fixed by double rubber tracker

- Foaming system: totally automatically continuous foaming, quantity

of foaming could be stepless adjustable

- Power of production ≥ 22KW

- Total power ≥ 35 KW

- Cutting:pneumatic piston driving, non-stop cutting via sliding

table

- Electronic controlling system: full-frequency PLC controlling

system

Description of PU Sandwich foaming line

- Two sets of conveyor rack: up conveyor is about 24m, down conveyor

is about 30m.They lead the steel sheet from the roll forming

machine to preheating room and to foaming,to cutting.

- One preheating room: It is built by heat-insulation material, and

it could heat up the steel sheet to 25-38 by heater.

- One set of PU two component Liquid mixing and injecting section for

foaming : it adopt Chinese high pressure pump. It have the

temperature control system and material-level monitoring system.

The tank of the material is about 150L. Two tanks.

- Foaming and double rubber device include motor driver system to

make panel.

- The width of belt board is 1250mm, the range of adjusting distance

between upper and lower frame belt board: min 25mm, max 200mm. And

the range of adjusting thickness of sandwich panel

:30mm,50mm,100mm.(30-50 for celling , 50-100 for wall)

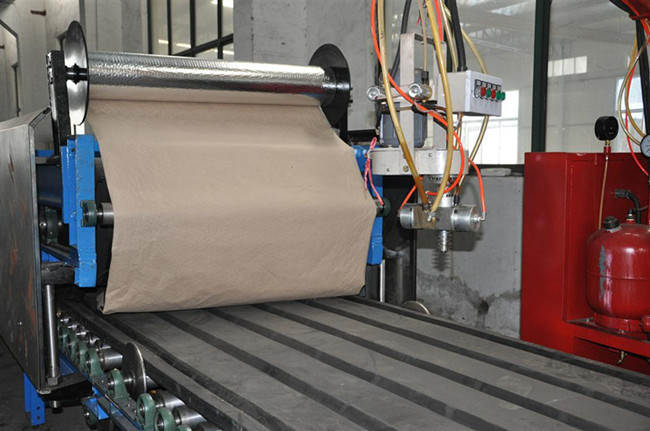

- Picture for reference

Panel automatically cutting system

- Cutting machine can move 2500mm longitudinally along product line,fly saw of the cutting machine can move transversely 1900mm,

Cutting machine moves longitudinally and transversely along the

slide way.

- Cutting machine adopts one-side blade band saw manner, cutting and

revolving after cutting. The cutting saw can revolve, so cutting in

two directions is realizable.

- There is panel tight-pressing system (pneumatic) in the cutting

machine;

- There is location limiter to limit longitudinal and transverse

motion of cutting machine.

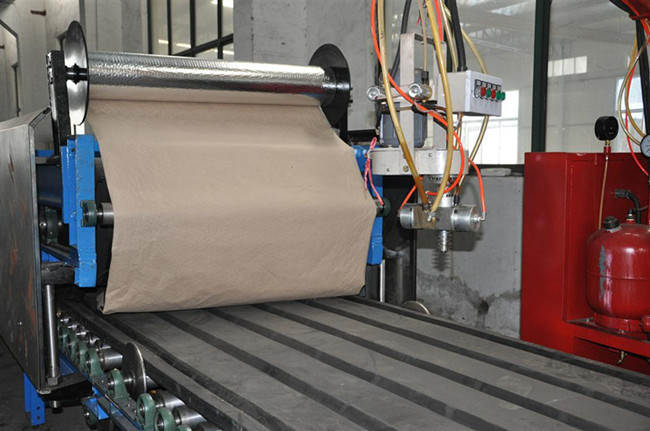

- picture of cutting system

Working flow

Coiler loading → adjustable feeding guide → steel panel forming →

steel sheet feeding guide → PU foaming → PU panel conveyor →

non-stop cutting

Introduction of company

We, Friendshachinery Co., Ltd, attaches great importance on

technology innovation,progress has been made on scientific

management as well as Co.,culture.Our manin products: Metal roof

&wall panels machines, C&Z purlin machines drywall

Stud-track forming machine,Metal decks machines,No- girder and

Column curves forming machines,Guard rails forming

machine,Downspout pipes forming machines and so on.

We can customize forming machine according to user's

requirements.And we can provide professinal service,high

quality,through design,and installation.

Warmly welcome to visit our factory no matter you are distibuters

or end-users,and looking forward to cooperating with you for mutual

benefits.

Contact Us

For more information, feel free to contact with us.

Skype:vivian_866

Mobile:86-15261519246

E-mail:sales02@roll-formingmachinery.com

vivianlucky866@gmail.com