Big Wave Corrugated Roof Panel Sheet Roll Forming Machine

Galvanised 3.5KW

General Description

It is the continuous cold roll forming machine for producing steel

structure panels.This seiries forming machine has more than 100

models for producing different panels, just like all kinds of roof

panels,wall panels, inner liner panels and so on.

We can designing and manufacture machines for forming different

profiles according to customers’requirements.

Material: | Color steel,galvanized steel | Material Thickness: | 0.6-1.5 mm |

Transportion Type: | Chain Drive | Forming Station: | 12—18 station |

Cutting Type: | Hydraulic Cutting | Power and Strength | 3.5KW,16Mpa |

Specifications of Roll Forming Machine

Coil Material | Thickness | 0.6-1.5mm |

Coil width | 1000-1250mm |

Yield Strength | 235-550Mpa |

Material | Color steel,galvanized steel |

Decoiler / Uncoiler | Coil Width | 1000-1250mm |

I.D | 498-508mm |

O.D | Max. 1800mm |

Roll Forming Machine | Forming Stations | 12-18 Stations ( Depend on Profiles ) |

Roller material | 45# steel, surface coated with 0.05mm hard chrome |

Diameter of shaft | 90mm |

Shaft material | High grade 45# steel |

Drive type | Chain transmission |

Forming speed | 0-15m/min |

Main power | 3.5KW |

Cutting | Cutting type | Hydraulic cutting |

Cutting power | 4KW |

CuttingTolerance | 10m+/-1.5mm |

Encoder | OMRON Brand |

Electrical control | Main component | PLC,frequency convertor |

Touch screen | PANASONICE or Custom-made |

Brand | From Japan,can be chosen by client |

Hydraulic Station | Hydraulic station | Famous Chinese brand |

Runout Table | Size | 1.2m*1m*1.2m*3pics |

Function | To support the finished panels |

Main Components

Decoiler / Uncoiler | 1 Unit |

Feeding Guide | 1 Unit |

Main Roll Forming Machine | 1 Unit |

Hydraulic Cutting Device | 1 Unit |

Hydraulic Station | 1 Unit |

PLC Computer Control Board | 1 Unit |

Output Table | 3 Units |

Processing Flow

Manual decoiler----feeding&guiding----rollforming----hydraulic

cutting--- run out table

Our Advantage

- High Quality

- Reasonable Price

- Good after Service

- 1 Year Warranty

- More Than 10 Years Experience

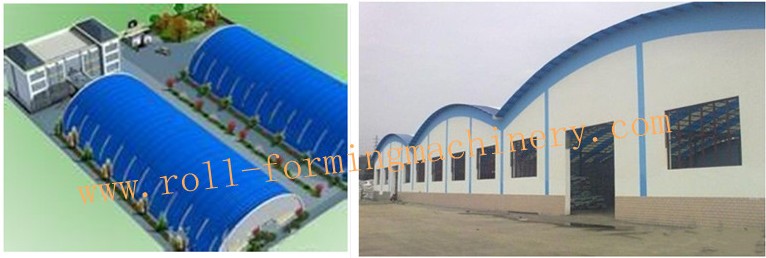

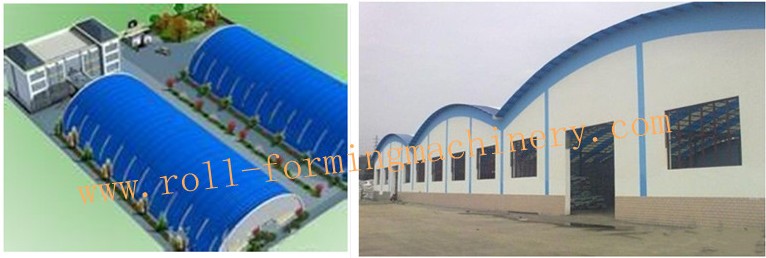

Application

- The roof panel used as the roofing of factory, warehouse, reliable

and safety installation is easy to realize

- Good toughness: with super toughness, Tere is no necessary to do

any treatment amontg the nail hole, it is sealing and can prevent

leaking water

- Long life: life ≥ 25 years, is an alternative to steel tile

- Corrosion resistance: strong acid, alkali, salt, anti-static,

anti-vapor corrosion, etc.

- Noise performance: noise performance is good, away from the noise.

Engineering Project

Introduction

We, Friendship Machinery Co.,Ltd, attaches great importance on

technology innovation,progress has been made on scientific

management as well as Co.,culture.China leading expert in designing

and manufacturing equipments for welding and cutting, automation

system and metal works. We use and produce high-technology

utilizing the most available robotic and automatic techniques.

Every work is uncompromisingly designed to improve our clients'

competitiveness and productivity.

We invest more on developing roll forming machine such as Metal

roof & wall panels machines,C&Z purlin machines drywall

Stud-track forming machines,Metal decks machines,No-girder and

Column curves forming machine,Guard rails forming

machines,Downspout pipes forming machines and so on.With fast

development ,very short period for construction and beautiful

external appearance,as well reasonable price was occupied in the

market of building industry.

EXCELLENT QUALITY AND COMPETITIVE PRICE !

CHOOSE US , CHOOSE THE BEST !

Thank you for your time !